UV Wood Printers for High-Quality Customization

Discover the Power of UV Printers in Crafting High-Quality Wooden Products

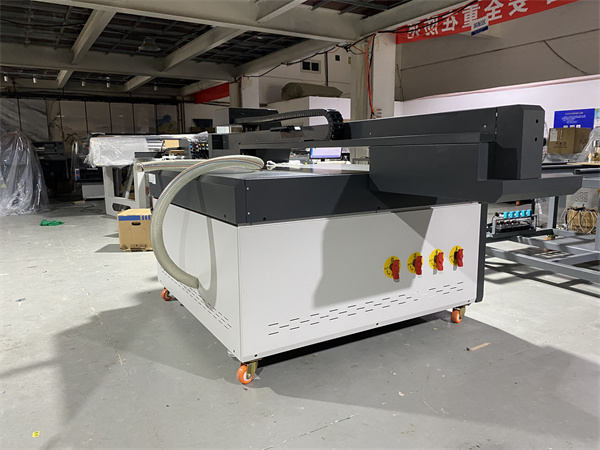

In the world of customization, where uniqueness and precision are highly valued, UV wood printers are revolutionizing the way we personalize wooden products. These printers use ultraviolet light to cure inks as they are printed, making them an efficient and versatile tool for producing high-quality, detailed custom designs on wood surfaces. Whether you are creating bespoke furniture, signage, or decorative items, UV wood printers offer an unmatched level of precision and durability. This article explores how UV wood printing works, its benefits, and its applications in various industries.

How UV Wood Printers Work

UV wood printers operate on a relatively simple yet highly effective mechanism. These printers use UV inks that are quickly cured (or dried) by ultraviolet light during the printing process. Unlike traditional inkjet printers, which rely on heat or air drying, UV printers instantly solidify the ink, resulting in vibrant and long-lasting prints. The ink adheres firmly to the wood surface, ensuring that the designs remain sharp and clear over time. The precision of UV printing technology allows for intricate and detailed images that would be difficult or impossible to achieve with conventional methods.

One of the key features of UV wood printers is their ability to print on different types of wood, including smooth, rough, and uneven surfaces. This flexibility makes them an ideal choice for a wide variety of custom wood products. The printers can handle various wood types, such as plywood, MDF, and solid wood, making them versatile tools for different industries, from furniture making to personalized gifts and home decor items. By using specialized print heads, UV printers can accurately place ink droplets on the surface without distortion, even when printing on irregularly shaped or textured wood pieces.

Benefits of Using UV Printers for Wood Customization

The use of UV wood printers provides numerous advantages that make them stand out from other traditional methods of customization. One of the most significant benefits is the superior print quality. UV printing allows for crisp, detailed designs with vibrant colors that pop. The ink is durable, scratch-resistant, and capable of withstanding exposure to sunlight without fading. This makes UV printing ideal for both indoor and outdoor wooden products that need to maintain their aesthetic appeal for years.

Another key advantage of UV wood printers is speed and efficiency. Traditional customization methods, such as hand painting or engraving, can be time-consuming and labor-intensive. With UV printers, businesses can produce high-quality customized products at a much faster rate, making them more productive and cost-effective. Additionally, UV printing reduces the risk of human error, resulting in consistent and precise designs every time. This efficiency is especially crucial for businesses dealing with high-volume orders or tight deadlines.

Moreover, UV wood printers are environmentally friendly. Unlike traditional printing methods that use solvent-based inks, UV printers use eco-friendly UV inks that emit little to no volatile organic compounds (VOCs). This makes UV printing a safer and more sustainable option for both the environment and the individuals working with the printers. The curing process also generates less waste, as there is no need for excess ink or solvent evaporation. This green aspect of UV printing is becoming increasingly important as industries move toward more sustainable practices.

Applications of UV Wood Printers in Customization

UV wood printers have found widespread use in various industries that require high-quality customization of wooden products. In the furniture industry, these printers are used to add intricate designs, logos, and personalized text to tables, chairs, and cabinets. The ability to print on wood surfaces of all shapes and sizes opens up endless possibilities for creating one-of-a-kind furniture pieces tailored to customer preferences. This customization enhances the appeal of the product, adding a personal touch that is highly valued by consumers.

In the signage and advertising industry, UV wood printers are commonly used to produce custom wooden signs that stand out with bold graphics and clear text. Businesses can create eye-catching promotional signs, storefront displays, and directional signage that leave a lasting impression on customers. Similarly, in the gift and home decor sector, personalized wooden items such as photo frames, plaques, and wall art are increasingly popular. UV printers allow artisans and businesses to add detailed and unique designs to these products, offering customers a truly personalized experience.

Furthermore, UV wood printers are widely used in crafting and hobbyist communities, where DIY projects and personalized gifts are in high demand. These printers make it easy for individuals to create customized wooden pieces at home or in small workshops, allowing for endless creative possibilities. Whether it’s engraving a family name on a wooden board or designing a custom wooden puzzle, the precision and versatility of UV printing enable hobbyists to bring their creative visions to life with ease.

Conclusion

UV wood printers have become a game-changer in the world of high-quality customization, offering precision, efficiency, and environmental benefits. Their ability to print on various types of wood surfaces and deliver vibrant, durable results makes them an indispensable tool for industries such as furniture making, signage, and home decor. With faster production times and eco-friendly inks, UV printers are not only helping businesses meet the demands for unique, customized products but also enabling a more sustainable approach to printing. As the technology continues to evolve, we can expect even more creative and innovative uses of UV wood printers in the future.

Local Production, Global Reach: UV Flatbeds Empowering Small Business Exporters

Local Production, Global Reach: UV Flatbeds Empowering Small Business Exporters

Inventory-Free Business Models: On-Demand UV Printing for Just-in-Time Production

Inventory-Free Business Models: On-Demand UV Printing for Just-in-Time Production

From Mass Production to Mass Customization: How UV Flatbeds are Reshaping Manufacturing

From Mass Production to Mass Customization: How UV Flatbeds are Reshaping Manufacturing

Emerging Market Solutions: Affordable UV Flatbeds for Developing Economies

Emerging Market Solutions: Affordable UV Flatbeds for Developing Economies