UV Printers: Revolutionizing the Printing Industry with LED Curing

How UV Printers with LED Curing Are Shaping the Modern Printing Industry

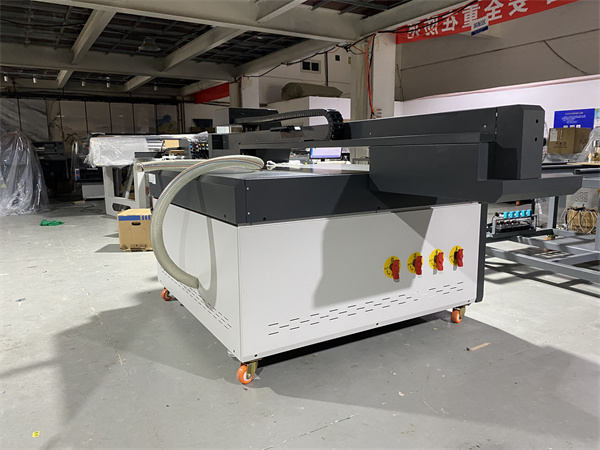

In recent years, UV printers equipped with LED curing technology have made a profound impact on the printing industry. These printers offer a level of efficiency and quality that was previously unattainable with conventional printing methods. With the rise of LED technology, UV printers are able to produce high-quality prints quickly, while also reducing energy consumption and environmental impact. This article delves into the key features of UV printers, the advantages of LED curing, and how these innovations are revolutionizing printing practices globally.

The Technology Behind UV Printers and LED Curing

UV printing involves the use of ultraviolet light to cure ink as it is applied to a surface. This process is fundamentally different from traditional printing, which relies on air-drying or heat to set the ink. Instead, UV printers use LED lights that emit UV radiation to instantly cure the ink, making it dry as soon as it touches the substrate. LED curing is the key innovation behind modern UV printers, offering a faster and more efficient printing process compared to older UV curing methods.

LED curing systems use much lower energy levels than traditional UV lamps, making them not only more energy-efficient but also more environmentally friendly. The LED lights emit little to no heat, allowing printers to work with a wider range of materials that might be sensitive to heat, such as plastics, films, and even fabrics. Additionally, LED curing technology reduces the need for the use of solvents, which are often harmful to both the environment and the health of operators. This makes UV printing an attractive option for companies looking to adopt more sustainable printing practices.

Advantages of UV Printers with LED Curing in the Printing Industry

The integration of LED curing technology into UV printers brings numerous benefits to both print service providers and their customers. One of the most significant advantages is speed. LED curing allows the ink to dry almost instantly, which dramatically reduces production time. In traditional printing methods, ink may take hours to dry, but with LED curing, the print is ready for handling immediately after printing. This quick turnaround is especially beneficial for industries that require fast production, such as packaging, signage, and promotional materials.

Another major benefit is the ability to print on a variety of materials. Traditional printers are limited to specific types of media, but UV printers with LED curing can print on a wide range of surfaces, including wood, metal, glass, ceramics, and even textured or flexible materials. This opens up a vast array of possibilities for creative applications, such as custom branding on products, personalized gifts, and even large-scale outdoor signage.

Moreover, the durability of prints produced by UV printers with LED curing is exceptional. The ink forms a hard, resistant coating that is resistant to fading, scratching, and smudging. This makes UV printing ideal for outdoor applications, where prints need to withstand the elements, as well as for items that require long-lasting colors and high-definition details. Whether it’s a banner displayed in direct sunlight or a customized product exposed to frequent handling, UV prints with LED curing provide excellent longevity.

Cost efficiency is also an important factor. Although the initial investment in UV printers with LED curing technology can be higher compared to traditional printers, the long-term savings are considerable. LED systems consume less energy, have a longer lifespan than traditional UV lamps, and reduce the need for costly consumables like solvents or additional curing agents. These factors contribute to a more cost-effective printing solution in the long run, making it a worthwhile investment for print businesses.

How UV Printers Are Shaping the Future of Printing

The role of UV printers with LED curing in the future of the printing industry is undeniable. As businesses strive to meet the demand for faster production times, higher-quality prints, and more sustainable practices, UV printing is stepping up to the challenge. The ability to produce high-resolution prints on a wide variety of materials, while reducing energy consumption and harmful emissions, positions UV printing as a forward-thinking solution for modern industries.

Moreover, as consumer preferences shift toward customized products, UV printing offers a unique advantage in personalization. From limited edition packaging to custom promotional items, the versatility and speed of UV printers with LED curing allow businesses to cater to the growing demand for individualized, on-demand products. This trend is expected to continue growing, especially as e-commerce and direct-to-consumer models become increasingly prevalent.

In conclusion, UV printers with LED curing are significantly reshaping the landscape of the printing industry. Their ability to produce high-quality, durable prints quickly and efficiently, combined with their energy-saving and environmentally-friendly characteristics, makes them a game-changer for businesses looking to stay ahead of the curve. As technology continues to evolve, UV printers will undoubtedly play an even more prominent role in revolutionizing the printing industry.

Summary: UV printers with LED curing technology are transforming the printing industry by offering faster, more efficient, and environmentally-friendly solutions. The ability to print on a wide range of materials, combined with enhanced durability and cost savings, positions UV printing as a revolutionary force in modern manufacturing and design.

Local Production, Global Reach: UV Flatbeds Empowering Small Business Exporters

Local Production, Global Reach: UV Flatbeds Empowering Small Business Exporters

Inventory-Free Business Models: On-Demand UV Printing for Just-in-Time Production

Inventory-Free Business Models: On-Demand UV Printing for Just-in-Time Production

From Mass Production to Mass Customization: How UV Flatbeds are Reshaping Manufacturing

From Mass Production to Mass Customization: How UV Flatbeds are Reshaping Manufacturing

Emerging Market Solutions: Affordable UV Flatbeds for Developing Economies

Emerging Market Solutions: Affordable UV Flatbeds for Developing Economies