uv printing on bottle--UV Printing Technology Applied to Bottles

An Innovative Way for Bottle Decoration

UV printing on bottles has emerged as a revolutionary technique in the packaging industry. This method involves using ultraviolet light to cure ink instantly on the surface of bottles, resulting in high - quality, durable, and vivid prints. Unlike traditional printing methods, UV printing offers a wide range of benefits that make it a preferred choice for many businesses.

Advantages of UV Printing on Bottles

One of the most significant advantages of UV printing on bottles is its high - resolution and sharp image quality. The ink cures immediately under UV light, preventing it from spreading or smudging. This allows for intricate designs, fine details, and vibrant colors to be accurately reproduced on the bottle surface. For example, in the perfume industry, brands often use UV printing to create elaborate logos and detailed product information on their glass bottles. The sharp and clear prints enhance the overall aesthetic appeal of the product, making it more attractive to consumers.

Another benefit is the durability of UV - printed bottles. The cured ink forms a strong bond with the bottle material, whether it's glass, plastic, or metal. This makes the print resistant to scratches, fading, and chemical damage. A beverage company that uses UV - printed plastic bottles found that the prints remained intact even after long - term storage and transportation, ensuring that the brand image and product information were always clearly visible to the end - users.

UV printing is also an environmentally friendly option. It uses less solvent - based ink compared to traditional printing methods, which reduces the emission of volatile organic compounds (VOCs). Additionally, the instant curing process means less energy is consumed during the printing process, making it a more sustainable choice for businesses aiming to reduce their environmental impact.

Process and Applications

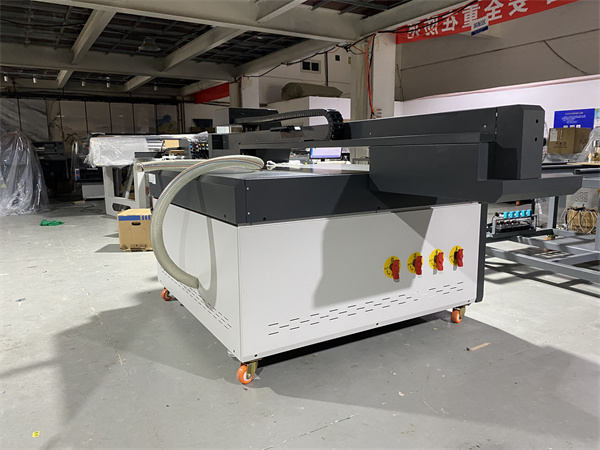

The UV printing process on bottles typically starts with preparing the bottle surface. This may involve cleaning and treating the surface to ensure proper ink adhesion. Then, the digital design is loaded into the UV printer. The printer sprays the UV - curable ink onto the bottle surface in a precise pattern, and immediately after that, UV lamps cure the ink, creating a permanent print.

UV - printed bottles have a wide range of applications. In the food and beverage industry, they are used for packaging juices, soft drinks, and alcoholic beverages. The ability to print high - quality labels directly on the bottle eliminates the need for separate labels, reducing production costs and improving the overall look of the product. In the cosmetic and personal care industry, UV - printed bottles are used to showcase brand identities and product features. For instance, a skincare brand may use UV printing to print detailed ingredient lists and usage instructions on its plastic bottles, providing consumers with important information at a glance.

In conclusion, UV printing on bottles is a game - changing technology that offers numerous advantages in terms of quality, durability, and sustainability. Its wide range of applications makes it a valuable asset for businesses across various industries.

Major New Product Release: SENA Introduces a Glass Lithography Printer Specifically Designed for Full-color Printing on Bathroom Doors

Major New Product Release: SENA Introduces a Glass Lithography Printer Specifically Designed for Full-color Printing on Bathroom Doors

The Silent Revolution: Noise-Reduced UV Flatbeds Transforming Workspace Environments

The Silent Revolution: Noise-Reduced UV Flatbeds Transforming Workspace Environments

Multi-Material Mastery: UV Flatbeds Printing on Composite and Hybrid Surfaces

Multi-Material Mastery: UV Flatbeds Printing on Composite and Hybrid Surfaces

Rapid Curing Science: The Physics Behind Instant UV Polymerization

Rapid Curing Science: The Physics Behind Instant UV Polymerization